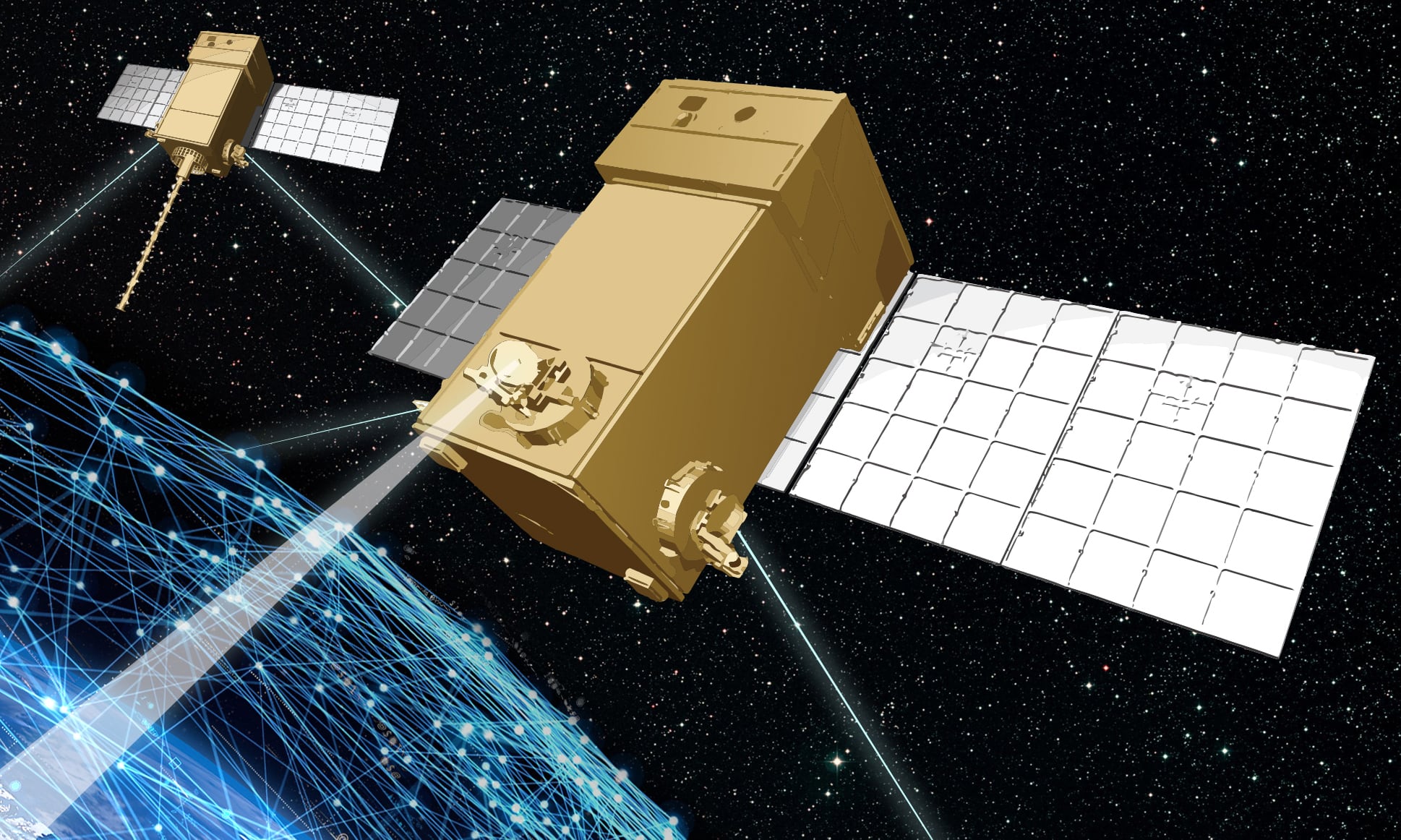

The Air Force is now using parts from a 3-D printer on its satellites.

A 3-D printed part will be on the AEHF-6, an advanced extremely high frequency satellite, when it is launched in 2019.

"A Remote Interface Unit, an aluminum electronic enclosure designed to hold avionic circuits, will be the first 3-D printed part certified for use on a Lockheed Martin military satellite," according to a company news release.

To get all the news about space and strategic systems delivered to your inbox every month, be sure to sign up for our Military Space Report newsletter.

The 3-D part was made using a process called Laser Powder Bed Fusion additive manufacturing, in which a laser melts and fuses aluminum metal powder layer-by-layer to build a part based on a digital design.

"By going from multiple machined parts to one 3-D printed part, the team was able to save time in the design and production cycle, as well as increase the quality and consistency of the units," Lockheed Martin said. "The lead time for manufacturing the part went from six months to only 1.5 months, with assembly time also being reduced from 12 hours to just three hours."