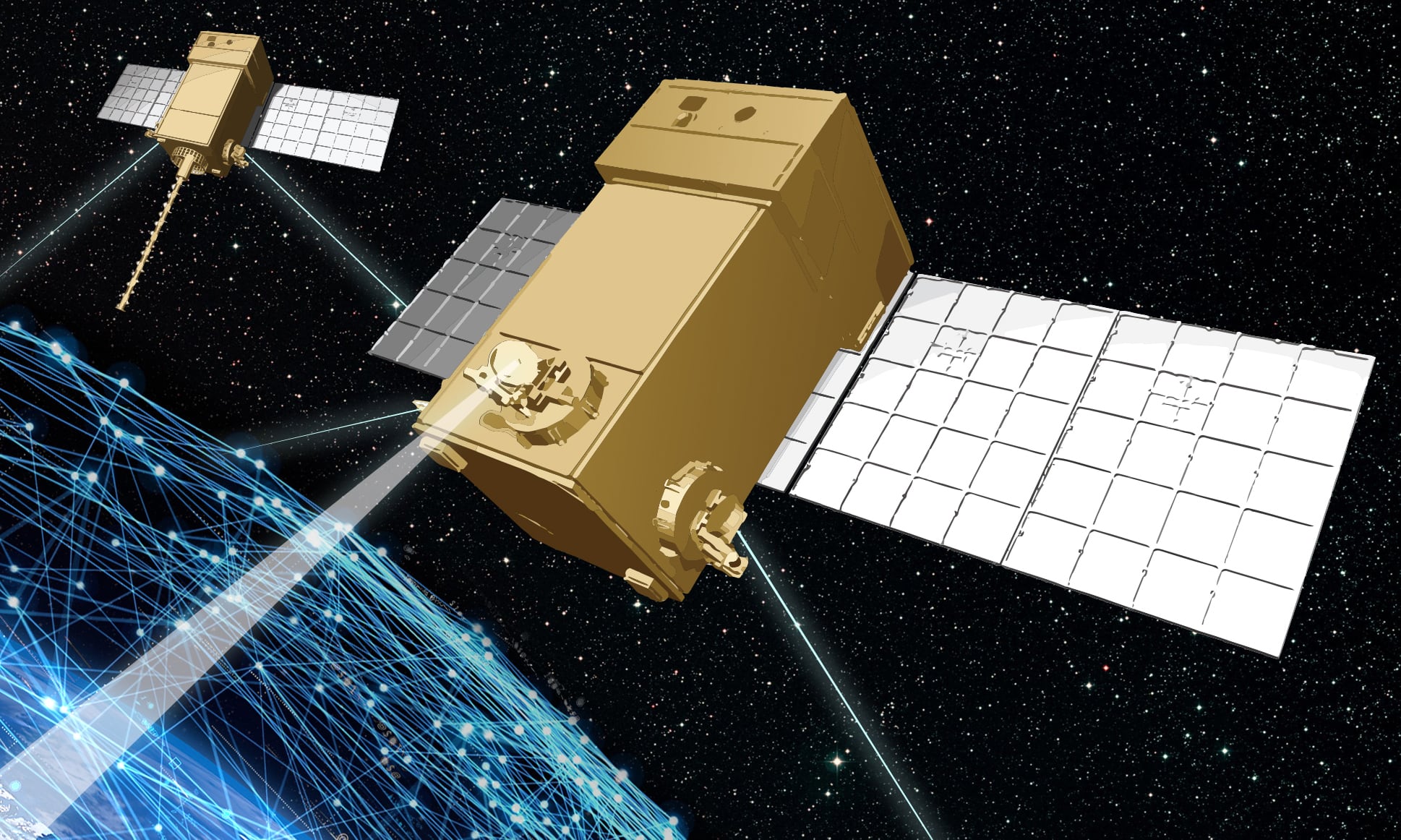

The U.S. Department of Defense relies on robust systems engineering to develop the weapons, satellites and communication systems needed to maintain superiority over foreign adversaries.

While the DoD has heavily utilized systems engineering since WWII, modern day defense systems are becoming more complex and call for a different approach to ensure projects stay within budget and are completed efficiently. Recent technological advancements have made model-based systems engineering a viable solution.

MBSE, a subset of digital engineering, involves the use of models, computer design, analytics and software development to create digital twins of prototype and operational systems, which dramatically reduces cost, improves quality and boosts efficiency.

In addition to enhancing development of weapon systems, MBSE can assist the Pentagon’s IT modernization efforts. DoD-wide adoption of MBSE would promote interoperability, accelerate digital transformation and ensure critical time and money are saved. Similarly, if embraced by all the services, MBSE can be a valuable tool to help satisfy the Biden Administration’s modernization efforts.

Improving Systems Development

Over the last six years, U.S. leaders have become more interested in MBSE technology due to its budgetary and time-saving benefits. Unlike older systems engineering solutions that require building paper-based engineering artifacts from scratch at the start of any project, MBSE models enable higher quality engineering processes that result in fewer defects and provide efficiencies through model reuse.

Moreover, when these models are used in conjunction with simulation tools, rapid prototyping and enhanced testing and verification are enabled, allowing testing to be conducted much earlier in system development resulting in fewer defects.

A study on the benefits of utilizing MBSE in the automotive industry found that when deployed during development, there was an average cost savings of 25-30 percent and an average time savings of 35-40 percent. Though DOD projects vary considerably in scope and complexity, similar results have been achieved. In 2018, the U.S. Air Force used digital modeling solutions when it created the T-7 Red Hawk, and the service slashed software development time by 50 percent and assembly hours by 80 percent.

For our military that is tasked with protecting the nation and safeguarding sensitivities, there are clear benefits to improving efficiencies and reducing the life cycle time needed to develop technologies. Not only is there a higher return on investment the earlier MBSE is applied in the life cycle of a project, but problems can be identified and resolved much earlier in the development process. When projects don’t utilize MBSE, more waste occurs in the form of “engineering artifacts,” or failed byproducts of the development process that no longer serve a purpose.

Enabling Digital Modernization

The U.S. spends one-third of its budget on IT legacy maintenance costs, a persistent issue the federal government continues to address through modernization funding and legislative initiatives. Despite cutting $2.8 billion in legacy maintenance in 2022, the DoD is still challenged by organizational siloes and an outdated systems infrastructure that significantly slows digital modernization efforts. MBSE can be a critical tool for accelerating digital transformation and improving cross-functional collaboration.

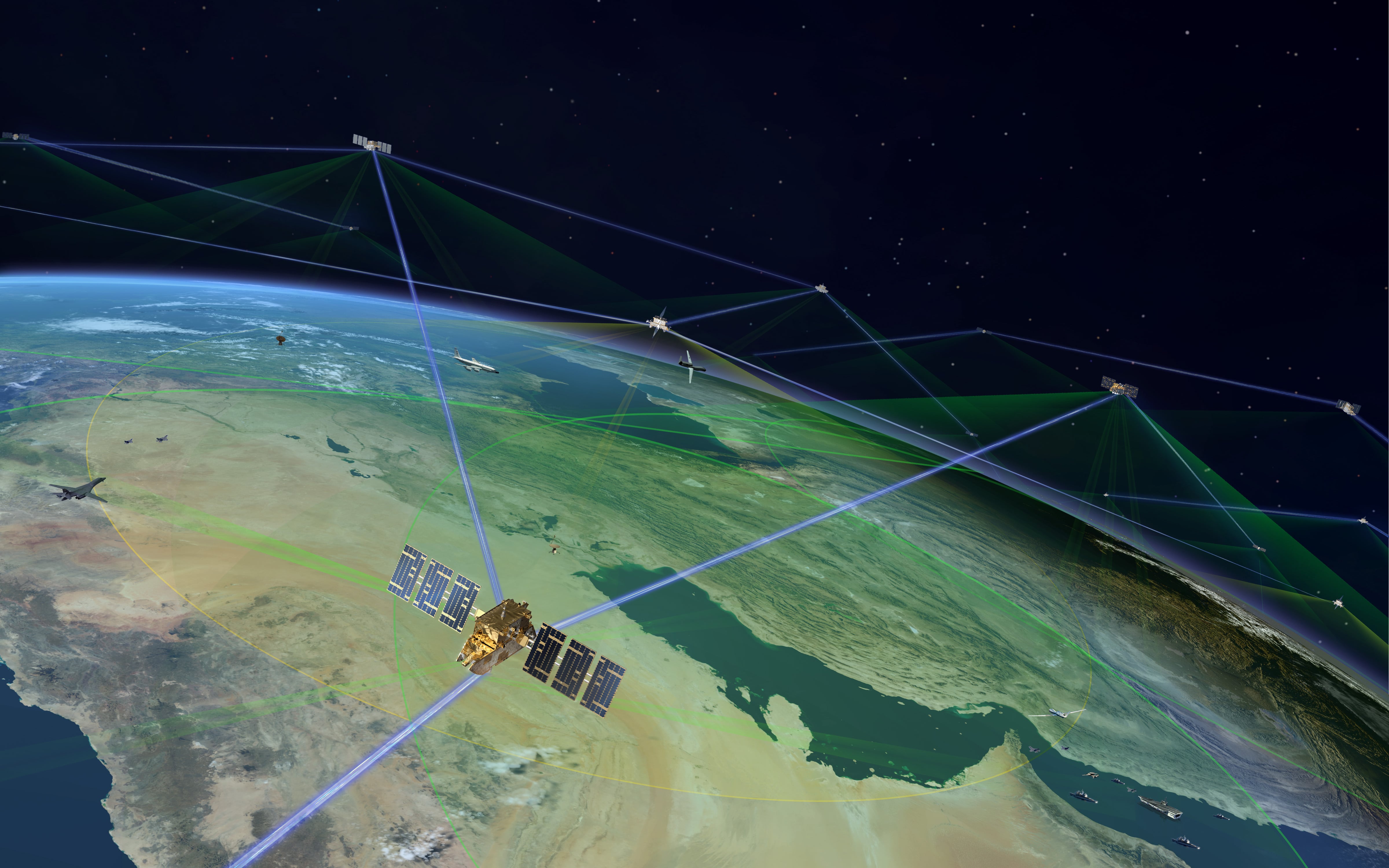

One way that MBSE can do this is by enabling digital threads that connect engineering data across a variety of sources, resulting in engineering rigor and traceability of data across the project life cycle. Engineering rigor through configuration management keeps the integrity of the project intact. Moreover, digital threads improve visibility into “authoritative sources of truth.”

These are data stores where requirements, architecture, schedule, risk data and other critical information are stored, making each database a different source of truth. Digital threads easily demonstrate how these data sources will connect, improving interoperability and traceability and accelerating system development time.

Over the last 15 years, the MBSE market has primarily been driven by companies in the automotive industry, but the defense and aircraft industries have wisely taken notice. As the DoD develops increasingly complex systems that require significant integration and testing, MBSE becomes more and more valuable as a systems engineering tool.

Because of its capability to reduce waste and promote efficiency and collaboration throughout the system development process, MBSE is an innovation that will give the DoD and America’s warfighters a distinct edge.

Al Guber is Senior Manager of Digital Engineering/MBSE at Arcfield, a provider of systems engineering and integration, C5ISR and digital transformation products and service for air, sea, land, space and cyber domains.

Have an Opinion?

This article is an Op-Ed and the opinions expressed are those of the author. If you would like to respond, or have an editorial of your own you would like to submit, please email C4ISRNET Senior Managing Editor Cary O’Reilly.