Raytheon is leveraging state-of-the-art, commercially available technology in computer aided design, 3-D technology and virtual reality to develop a training and simulation center that can provide remote access across the world.

The company has developed two Immersive Design Centers in Tucson, AZ and Andover, MA, which features Cave Automatic Virtual Environment technology. The CAVE, as it's known, is described by the company as "a large-scale virtual reality environment where teams can collaborate using three-dimensional (3-D) stereoscopic immersive visualization. Inside the CAVE, up to 20 participants actively support reviews of models, simulation results and data sets and collaborate in new ways to assess, evaluate and create solutions to nearly any problem in the Raytheon product life cycle."

C4ISRNET had an opportunity to experience Raytheon's CAVE at its Andover location recently.

Officials provided three operational examples for how the system can be used. In the first example, demonstrators activated the system to place participants inside a 3-D command and control shelter. This allows for trainers, maintainers or operators to get a feel for what the shelter actually looks like – down to the actual dimensions of the facility – as well as be able to interact with it.

Using a video game controller and infrared cameras mounted atop the 72 LCD screens that make up the CAVE, the instructor is able to interact with the 3-D computer model. In this case, the instructor was able to pull radars from their racks and rotate them 360 degrees. From here, participants can be shown how to repair the system down to individual wires.

In the second example, the instructor pulled up a Patriot missile battery in the field and demonstrated how this could train soldiers how to perform various maintenance tasks, from wiring to configuration.

Third, the instructor demonstrated how the CAVE helps perform depot design and facility layout. Laser scanners capture the entire layout of a facility including where furniture or assets exist, allowing programmers, engineers or the end users to virtually retrofit or place new equipment prior to purchasing anything.

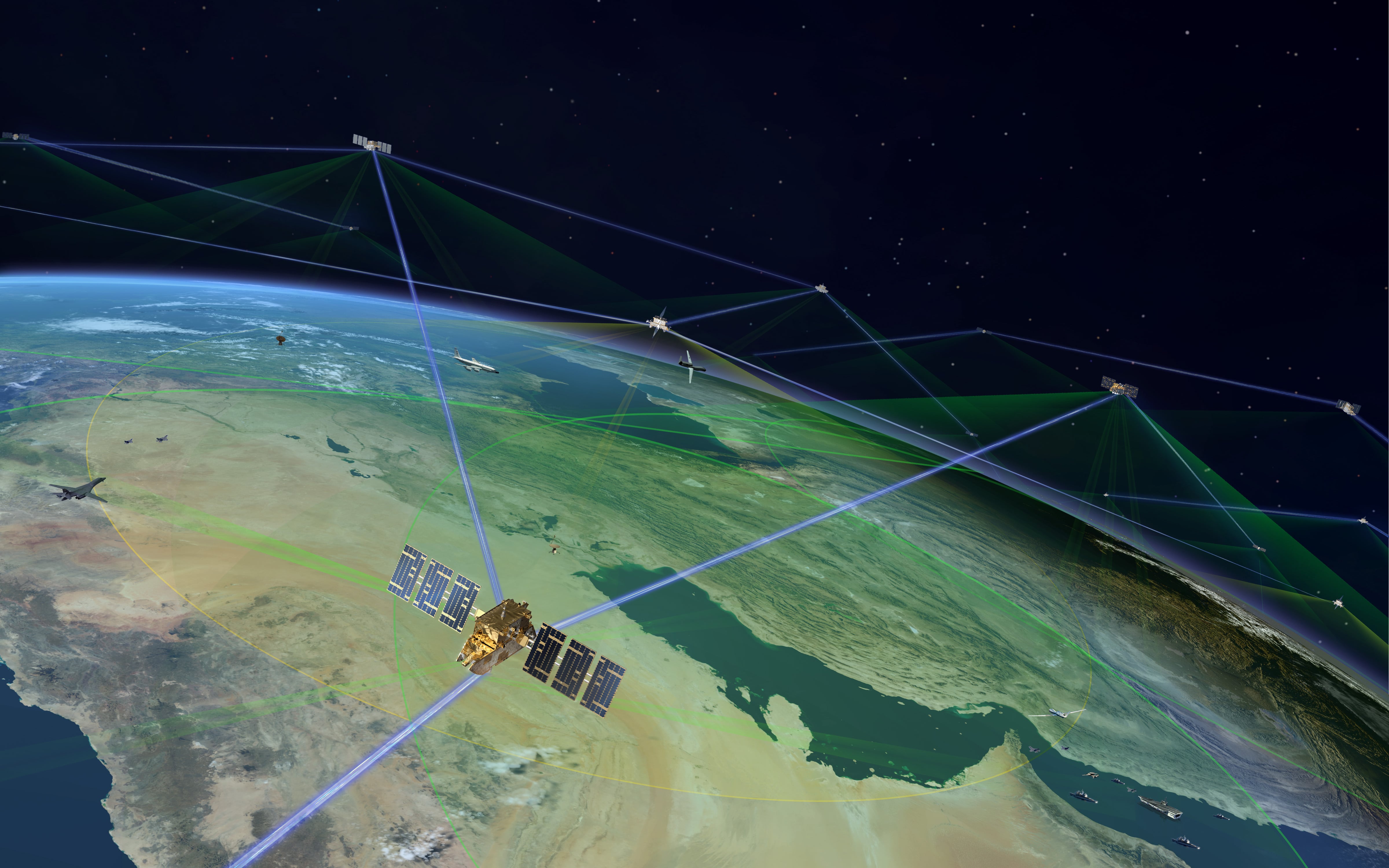

One of key aspects of the center is its collaborative capabilities. The facility allows for remote collaboration from screen shares, video teleconferencing and even virtual avatars. Distance is no longer a valid excuse, Raytheon officials said, when trying to work on repairs to a system. With the CAVE, an end user in Germany can view walk-throughs and train on how to repair a particular system with actual avatars of trainers on the other end. This means a trainer won't have to hop on a plane overnight to help train personnel on repairing a critical system.

Officials at Raytheon said the genesis of this capability came from listening to their customers on the way the military standards are going and leveraging computer-aided design models and virtual reality as the solution to getting at these standards. They conducted a lot of trade studies to see how to be the tip of the spear and implement this not as a science project but as a design tool. In terms of return on investment, officials said the system paid for itself in six months, adding that this return on investment is one of the benefits of the CAVE as a design tool.

Mark Pomerleau is a reporter for C4ISRNET, covering information warfare and cyberspace.