WASHINGTON — The Defense Department’s emerging technology research arm will invest in new materials and processes that could enable manufacturing in space and on the moon’s surface.

To that end, the Defense Advanced Research Projects Agency is launching the Novel Orbital and Moon Manufacturing, Materials and Mass-efficient Design program, or NOM4D.

“NOM4D’s vision is to develop foundational materials, processes and designs needed to realize in-space manufacturing of large, precise and resilient Defense Department systems,” said Bill Carter, program manager in DARPA’s Defense Sciences Office, in a press release.

RELATED

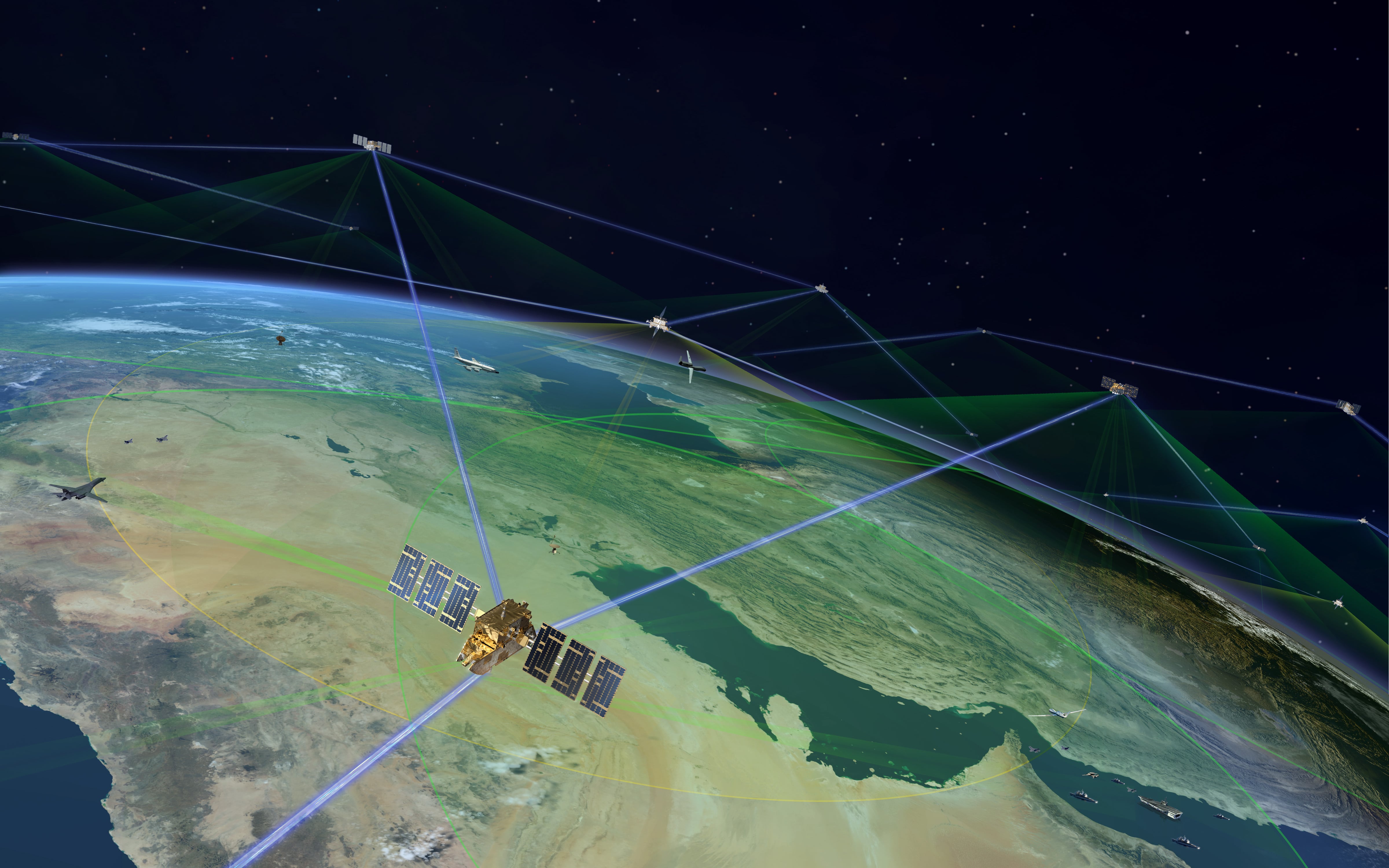

DARPA is launching the program in response to the natural limitations of rocket launches in placing larger structures and systems in orbit, the agency said. While the launch industry has expanded significantly in recent years, with dozens of new providers entering the fray, rocket launches are inherently limited — even the largest rockets have weight and volume restrictions. The solution? Place smaller pieces of a structure on orbit with multiple launches, and then assemble them in space. Or better yet, collect materials from the moon to build with.

“We will explore the unique advantages afforded by on-orbit manufacturing using advanced materials ferried from Earth,” Carter said. “Large structures such as antennas and solar panels can be substantially more weight efficient, and potentially much more precise. We will also explore the unique features of in-situ resources obtained from the moon’s surface as they apply to future defense missions.”

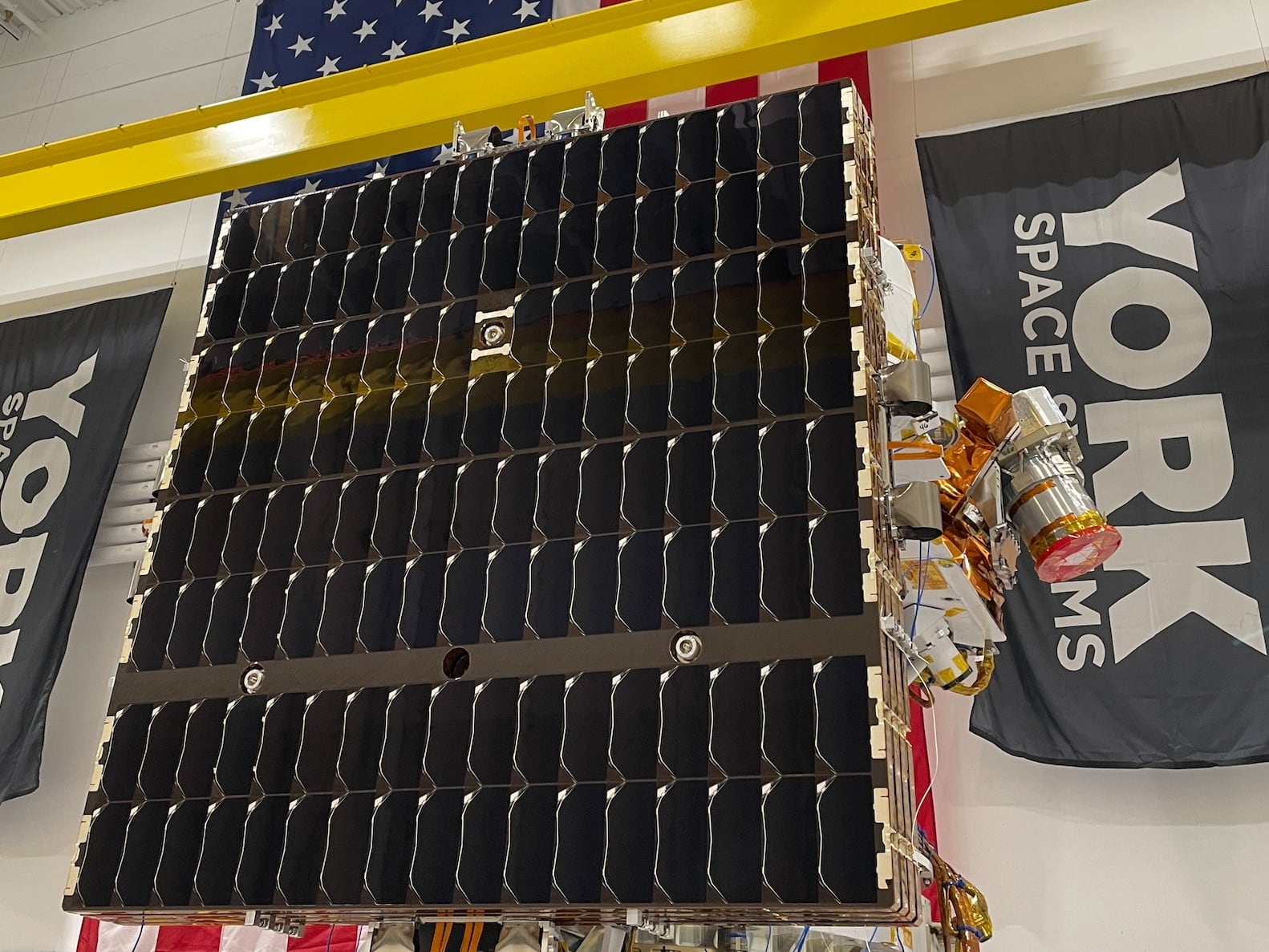

Manufacturing in space could also enable more flexibility in the design of space systems. Today, most satellites are designed to be as compact as possible in order to be integrated with and launched on rockets. But by assembling systems in space, systems could be designed without some of those volume restrictions, allowing them to be more mass efficient.

“We’re looking for proposers to come up with system designs that are so mass efficient that they can only be built off-earth, and with features that enable them to withstand maneuvers, eclipses, damage and thermal cycles typical of space and lunar environments,” Carter said. “Given the constraints of ground test, launch and deployment, the traditional approach to designing space structures is not likely to result in dramatic improvements in mass efficiency. In order to take the next step, we’ve got to go about materials, manufacturing and design in a completely new way.”

The idea of assembling systems and structures in space isn’t new. Famously, the International Space System was assembled in space using a number of components individually launched into space.

“People have been thinking about on-orbit manufacturing for some time, so we expect to demonstrate new materials and manufacturing technologies by the program’s end,” Carter added.

With NOM4D, DARPA will work with participants over three 18-month phases to develop precise, mass efficient structures that could be used for on-orbit construction. Each phase will focus on one of three applications: large solar arrays, large radio frequency reflector antennas, and segmented infrared reflective optics.

The agency will host a proposers day webinar on Feb. 26 and expects to release a broad agency announcement solicitation in February.

Nathan Strout covers space, unmanned and intelligence systems for C4ISRNET.